PRODUCTIVITY

PRODUCTIVITY BREAKDOWNS

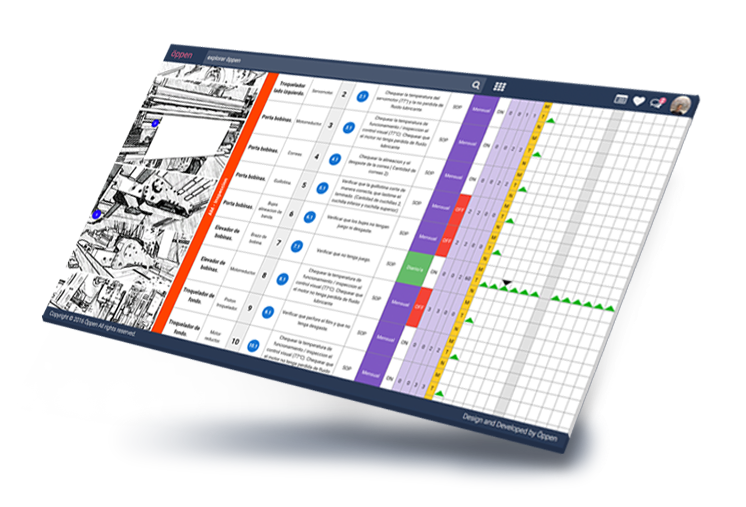

BREAKDOWNS84% of the plants recognize the importance of digitizing the factory. Only 18% have a plan to achieve it.

Don’t miss your chance to do it! öppen.io accompanies you every step of the way.

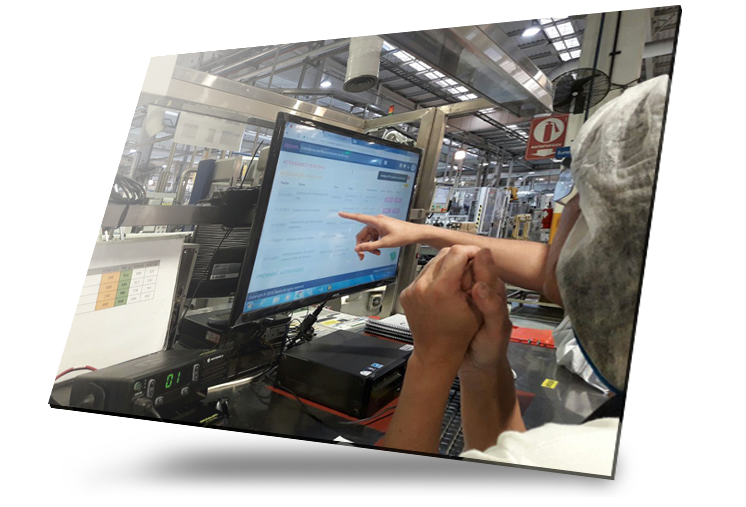

Marcelo Sosa

OPERATIONS MANAGER

HOLLIDAY SCOTT S.A.

"We are very pleased with the support of their consultants and programmers: they have always been very willing to adapt to our business rules and the changing tax systems of our country. Particularly at Holliday, it has allowed us to generate all the documentation of production of the Good pharmaceutical manufacturing practices at the highest level and we have been using it successfully for more than 10 years.”